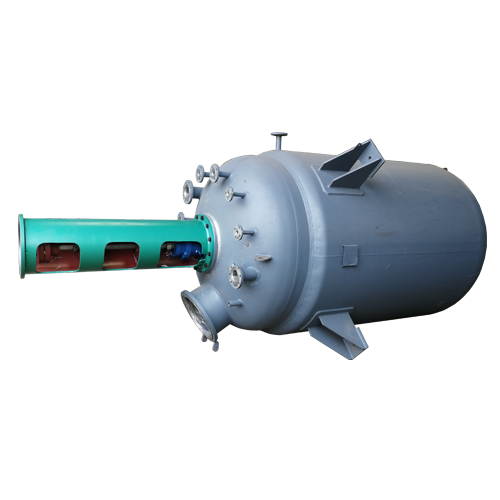

Industrial Reactor

Your Current Location:Home > Product Center > Industrial ReactorThe working principle of the magnetic seal reactor

Magnetic drive is a new type of transmission sealing technology developed in the 1980s. The key component of the magnetic reactor, the magnetic coupling transmission is a transmission device that uses permanent magnetic materials for coupling transmission. It has changed the traditional mechanical seal and packing seal through the shaft sleeve or packing to seal the dynamic seal structure of the stirring shaft, and replaced it with a static seal structure , The medium in the reaction kettle is completely in the sealed cavity formed by the kettle body and the sealing cover body, which completely solves the insurmountable leakage problem caused by the dynamic seal of the packing seal and the mechanical seal, so that the reaction medium will never leak or pollute.

When the power is turned on, the temperature and speed sensors installed on the reactor will send the corresponding signals to the reactor PID controller. The controller will display the corresponding signals and compare the temperature signal with the temperature setting signal. Afterwards, control the heating system that comes with the reactor, and adjust the heating power in PID regular on-off or phase modulation to make the actual temperature consistent with the set temperature. At the same time, after the speed signal is compared with the speed setting signal, the motor speed is adjusted by PID law, so that the actual speed is consistent with the set speed.

Open reactor

The reaction kettle body and the reaction kettle cover adopt the tapered surface and the arc surface line contact sealing form. Tighten the main bolts to press each other to achieve a good seal. When tightening the main bolts, the tightening torque must not exceed the range of 80-120NM. To prevent the sealing surface from being squeezed and overloaded, the sealing surface should be specially protected. When installing the reactor cover, the reactor cover should be started up and down slowly to prevent the sealing surface between the reaction kettle body and the reaction kettle cover Hit each other. To tighten the main nut, it must be tightened symmetrically and gradually in multiple times. The force must be uniform to achieve a good sealing effect.

The main parts of the autoclave-the cover (the whole forging is processed by the lathe after the flaw detection is qualified), the kettle body (the lathe is turned into a hollow after the whole forging is qualified for the flaw detection), the strong magnetic coupling stirrer, the high temperature and high pressure needle valve, the lower mixing part, the internal cooling The materials used for coils, temperature measurement parts, and submersible pipes are 0Cr18Ni9 (304), 0Cr18Ni10Ti (321), 00Cr17Ni14Mo2 (316L), titanium, Hastelloy, Monel, nickel, zirconium, tantalum, 904L, It is made of silver, tetrafluoro, etc., and can also be built-in titanium / Hastelloy / Monel / nickel / zirconium / tantalum / silver / tetrafluoride and other inner tanks, and can be sprayed with high temperature resistant tetrafluoride layer.

Through the structural design and parameter configuration of the container, the production reactor realizes the heating, cooling, evaporation, cooling and low-speed stirring and mixing functions required by the production process, so that the reaction medium can undergo physical or chemical reactions in the reactor.

The reactor is widely used in petroleum, chemical industry, rubber, pesticides, dyes, medicine, food, and is a pressure vessel used to complete vulcanization, nitration, hydrogenation, alkylation, polymerization, condensation and other processes.

Production kettles are widely used in petrochemical, universities, research institutes, national defense technology, aerospace and military industry, medicine and food, hydrothermal synthesis, dyes, metallurgy and other units.

The contact materials of the kettle body are mainly made of stainless steel, and titanium materials (TA1, TA2), nickel materials (Ni6) and composite steel plates can be manufactured according to the requirements of different media. As well as the closed reactor body with manholes, the opening on the cover can be designed according to user requirements; heating methods include jacket steam circulation heating, jacket heat conduction oil circulation heating, jacket electric heating, and outer coil (semi-circular) Coil) heating and other forms are optional for users when ordering. For the inner surface of the kettle with polishing requirements, it can reach the level of mirror polishing, and the high-viscosity materials are processed into a tapered bottom, which is convenient for discharging and cleaning.

Hydrogenation reaction refers to a reaction process in which hydrogen interacts with other compounds, usually in the presence of a catalyst. The hydrogenation reaction belongs to the category of reduction.

There are two types of commonly used hydrogenation reactors and reactors: one type is used for liquid phase hydrogenation process of high boiling point liquid or solid (solids need to be dissolved in solvent or heated and melted) raw materials, such as fat hydrogenation, heavy oil Hydrocracking, etc. Liquid phase hydrogenation is usually carried out under pressure, and the process can be batchwise or continuous. Intermittent liquid phase hydrogenation often uses an autoclave or bubbling reactor with a stirring device. The continuous liquid-phase hydrogenation can adopt a trickle bed reactor or a tubular reactor with three-phase continuous flow of gas, liquid and solid. Another type of reactor is used for continuous gas-phase hydrogenation processes, such as atmospheric gas-phase hydrogenation of benzene to cyclohexane, high-pressure gas-phase hydrogenation of carbon monoxide to synthesize methanol, etc. The reactor type can be tubular or tower. In the food field, it is mainly used to produce sorbitol, xylitol, maltitol and other continuous hydrogenation reactions, as well as intermittent hydrogenation reactions.

The stirring form of batch hydrogenation reactor is generally three-layer combined stirring, including paddle stirring, self-priming stirring and disc turbine dispersion stirring, which can also be selected according to user requirements. Our self-priming stirring paddle adds a set of riders, which can make the gas enter the hollow shaft of the stirring paddle more smoothly, and fully mix with the liquid gas.

Zhengwei hydrogenation reactor is equipped with CT4 explosion-proof motor and explosion-proof control box. All electrical components are explosion-proof configuration, so that customers can use it safely.

Polymerization is the process of converting low-molecular-weight monomers into high-molecular-weight polymers. Polymers have important properties such as plasticity, fiber formation, film formation, and high elasticity that low-molecular-weight monomers do not have. They can be widely used as plastics. , Fibers, rubber, coatings, adhesives and other high-molecular materials. This material is composed of more than one structural unit (monomer), a polymer compound synthesized by repeated reactions of monomers.

The polymerization reactor is generally equipped with condensation collection or condensation reflux device, which is conducive to the synthesis of high molecular polymers. High-molecular organic polymers are generally high-viscosity materials, and the bottom of the reactor can be made into a cone according to customer requirements to facilitate discharge and cleaning. The reactor agitator is generally made of a ribbon type or an anchor frame type, with a high-power stirring motor, to achieve the full mixing of the materials in the kettle.

Mechanical seal (mechanical seal) refers to at least a pair of end faces perpendicular to the axis of rotation under the action of fluid pressure and the elastic force (or magnetic force) of the compensation mechanism and the auxiliary seal to keep fit and slide relative to prevent fluid leakage. Device. The main components include moving ring, static ring, sealing ring, cooling device and compression spring.

The mechanical seal has a large rotating torque, suitable for stirring high viscosity media, and its cost is relatively economical. However, the pressure resistance of mechanical seals is not as good as that of magnetic seals, and can withstand up to 1.6MPa pressure. When used in high temperature conditions, the mechanical seal needs to be equipped with a cooling water jacket for cooling.