Reactor System

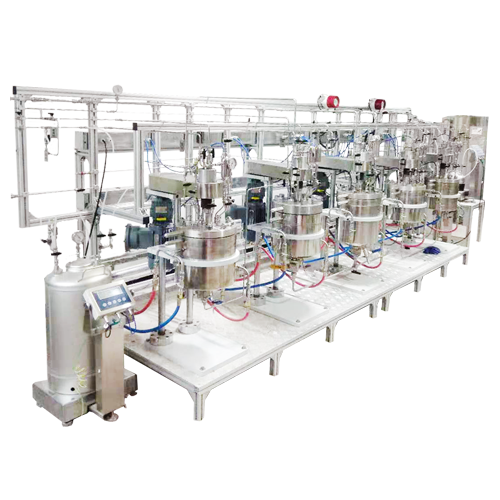

Your Current Location:Home > Product Center > Reactor SystemUnder normal production conditions, the continuous reactor should operate continuously and stably, and the various variables of the reactor must be maintained at a certain constant value. Therefore, the control systems of continuous reactors are mostly fixed value control systems.

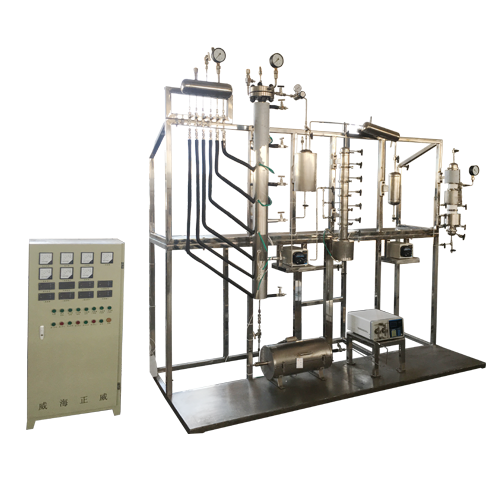

The fixed-bed reactor is a device in which fluid undergoes chemical reaction through a bed formed by static solid particles. Specifically, it can be divided into gas-solid phase catalytic reactor and liquid-solid phase catalytic reactor. Among them, gas-solid phase catalytic reactors in which gaseous reaction materials undergo chemical reactions through a bed composed of solid catalysts are the most widely used in chemical production.

Weihai Zhengwei Machinery Co., Ltd. is a high-tech enterprise integrating complete independent research and development, manufacturing, and marketing systems. It can provide special customized design and manufacturing according to the volume, working temperature, and working pressure provided by customers.

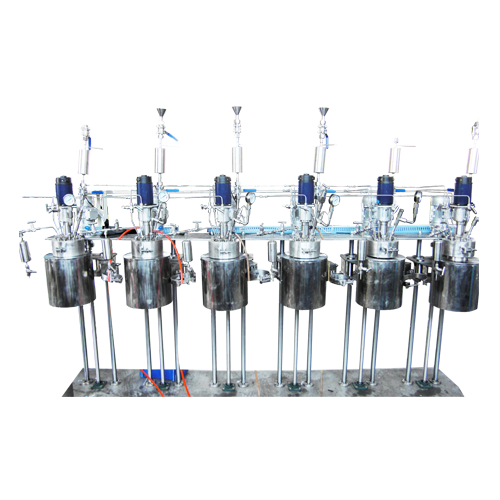

There are many types of industrial hydrocracking equipment, which are divided into one-stage method and two-stage method according to the function of the reactor.

The two-stage method includes a two-stage reactor, the first stage is used as a hydrofining section to remove nitrogen and sulfide in the feedstock oil. The second stage is the hydrocracking reaction section.

Only one or several reactors in one-stage process are used in parallel. The process flow of the one-stage fixed-bed hydrocracking unit is that the raw oil, circulating oil and hydrogen are mixed and then heated and introduced into the reactor.

The reactor is equipped with a granular catalyst, and the reaction product is separated from the gas by the high-pressure and low-pressure separators, and then the liquid product is distilled in the fractionating tower to obtain the product petroleum fraction.

The one-stage method has a relatively low cracking depth and generally uses vacuum wax oil as the raw material to produce middle distillate oil. The two-stage method has a deeper cracking depth, and generally mainly produces gasoline.

The heating method of the reaction kettle is jacketed heat-conducting oil circulating heating, equipped with heat-conducting oil heating oil furnace and hot oil circulating pump, under the condition of PID program temperature control, to achieve stable heating and cooling in the kettle.

Weihai Zhengwei Machinery Co., Ltd. is a high-tech enterprise integrating complete independent research and development, manufacturing, and marketing systems. It can provide special customized design and manufacturing according to the volume, working temperature, and working pressure provided by customers.